Students in an interdisciplinary fall course learn to observe the living world in search of design strategies grounded in planetary health.

RISD-HMG Research Partnership Explores Tangible Futures in Advanced Biodesign

Students in a fall research studio created in collaboration with the Hyundai Motor Group (HMG) experimented with biopolymers such as cellulose, gelatin, and starch to create green bioplastics that might someday replace less Earth-friendly materials used in the automotive industry. Led by Industrial Design Critic Max Pratt 19 ID/MID 21, Nature Lab Biodesign Research Associate and Industrial Design Critic Jessica Smith, and Industrial Design Critic Eliza Squibb 13 TX, the course is part of an ongoing research partnership between RISD and HMG examining the convergence of biodesign and biomimicry, advanced art and design practices, and the future of mobility across the globe.

“HMG and RISD are working together to create the just future we all wish to envision,” says Provost Touba Ghadessi, “not only for mobility solutions, but for generations of humans who share this planet and want to replenish its resources.”

Building on previous courses as well as summer research intensives in the Edna W. Lawrence Nature Lab with visiting Hyundai, Genesis, and Kia designers, this fall’s course is focused on examining natural environments, systems, processes, and organisms with the intent to design a more circular and less harmful human-planet relationship.

“We’re devoting the majority of the semester to student-directed biodesign research that leads to solutions with real-world applications and impacts,” says Squibb. “We’re encouraging students to pick one material—for example, a mycelium foam for automotive interiors—and push it as far as they can.”

The class has access to Nature Lab resources, including microscopes, 3D scanners, and the lab’s incredible collection of natural organisms, as well as the expertise of its staff, including Houghton P. Metcalf, Jr. (HD 96) Director Jennifer Bissonnette and Collections Manager and Staff Biologist Benedict Gagliardi.

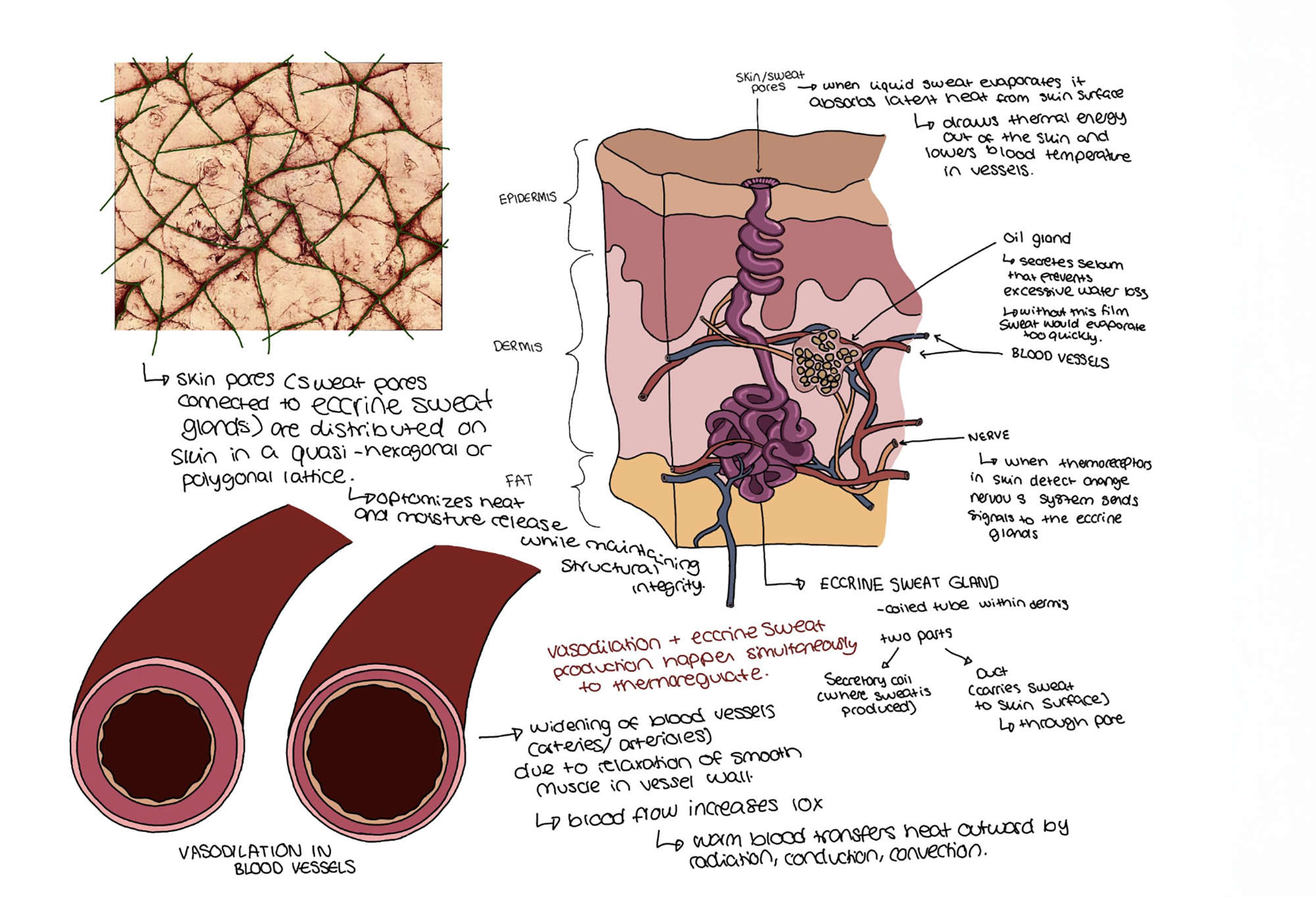

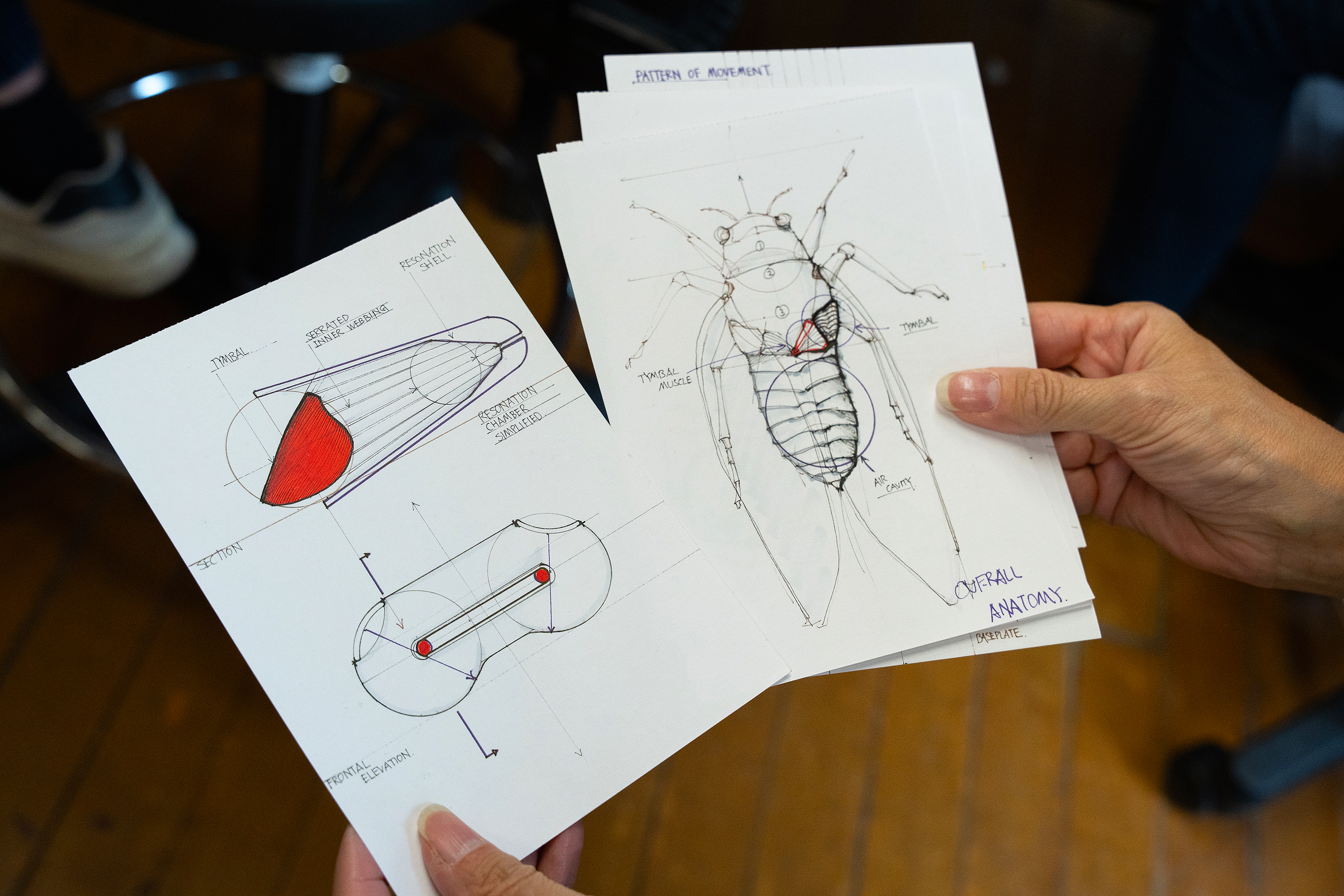

“The fall curriculum includes observation from nature and a series of short introductory assignments focused on exploring the biodesign process,” notes Smith. “We’re focusing on advanced research techniques, such as microscopy imaging, 3D scanning, and material testing.”

In late October, students shared their initial research projects with visiting critics Jean J. Huang and Ben Linder, faculty members from Olin College of Engineering in Needham, MA, who have been supporting the Regeneration Studio since last year. Many of the projects focus on developing strong but lightweight and Earth-friendly materials that would keep passengers safe in collisions.

“We’re devoting the majority of the semester to student-directed biodesign research that leads to solutions with real-world applications and impacts.”

Junior Lara Tekindur 27 ID is taking inspiration from the suture structures in a turtle’s shell and a woodpecker’s beak in her quest to design autobody materials with irregular, built-in crumple patterns that would redirect the force of impact away from passengers during a crash. Mars Huang 27 ID is looking into the incredibly strong club (or front claw) of the peacock mantis shrimp, which is capable of shattering aquarium glass without sustaining damage.

Other students are focusing on the driver’s experience and how to build cultural trust in driverless vehicles. Grad student Jason Xu MID 27 is examining the effects of natural sounds on drivers and studying the mechanisms that cicadas and other arthropods use to create sound. Senior Ryan Lee 26 ID is studying the psychological and physiological effects of water on people and considering how to harness those effects for passengers in driverless vehicles.

Sean Lee 26 ID, who lives with his grandmother when he’s not in school, is working on improving mobility devices for elderly people, like walkers and wheelchairs. He is studying natural inspirations, like the ball-and-socket joints of the sea urchin, for clues about how to design wheels with better shock absorption.

In some cases, Pratt points out, the issue is not about creating the best design, but a better one that can be made cost-effectively at scale. “The key is finding a balance between the design you really want and what is feasible to manufacture,” they note.

As the semester continues, students will refine their designs and seek additional natural inspirations for mobility-related problems like energy efficiency, aerodynamics and stability, noise reduction, high-performance surfaces, and the ability to shed water. They will contribute their innovative ideas, sketches, and early prototypes to the growing archive of mobility solutions the RISD-HMG partnership is producing.

Top image: Brown | RISD Dual Degree students Scarlett Meza and Alysha Lai mix bioplastics on a hotplate and pour them into molds made of corrugated plastic.

Simone Solondz / photos by Kaylee Pugliese

November 17, 2025